Here is a sleek Mortimer hammer double from the 1880s with an unusual safety. Like many old guns, this one has suffered at the hands of one or more bodgers in the past. The head of the right hammer screw had been snapped off, leaving the shank in the tumbler, the screw slots have had the obligatory damage inflicted upon them and the safety allowed the right lock to fire when applied.

Here we go.

To remove the broken screw from the tumbler, I drilled the screw to the root diameter of the threads (6 BA) and then turned the remaining piece out using a sharp tool. The new screws were all made in the usual fashion.

Next up were the toplever screw and the breech screw. The toplever screw was also broken off but the two threads under the head were still holding the head on. Removal of the broken shank was via the same procedure described above.

The new toplever screw ready to be engraved.

The breech screw and guard screws in this gun have heads that taper and fit into mating tapers similar to a wood screw. This means that the slot gets shorter in length as the depth increases. When a wanna-be gunsmith uses a screwdriver that "fits" the slot lengthwise at the top (but not the bottom) this is what happens.

To correct the damage, I machined a new seat for the screw head. It is now a straight-sided, shouldered seat but since I'm making new screws that is of no consequence. Normally I would have kept the tapered seat but the damage was so extensive that once the hole "cleaned up", the new screw head would have intruded into the engraving on either side.

The guard screws and guard had suffered the same fate. In this instance I was able to salvage the holes while keeping the same type of screw head.

Lest you think that repairing the guard screws was as simple as machining the screw seats, making news screws, indexing them, contouring them, engraving them and case hardening them, fear not.

The screw holes in the stock were in fact, made of glue. Apparently they were stripped out at some point so the hack did what anyone worthy of the title would do, use glue to make new threads.

I drilled the holes, turned threaded inserts (2 BA) and secured them with epoxy.

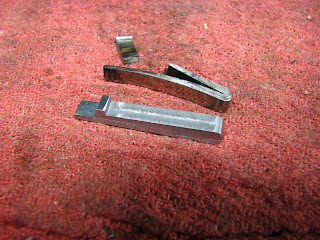

Here is one of the new guard screws. Thin gunmaker slots are used throughout in order to discourage tampering. The slot is deeper than the lighting of the photo makes it appear.

Here are photos of the finished screws. These photos were taken after repair of the safety and final assembly. I will detail the design of the safety after.

A safety on a hammer gun (with rebounding locks, no less) is very uncommon. This safety is even more unusual. It consists of a vertical lever which is located at the front of the triggerguard that engages a sliding plate inside the action (on top of the triggerplate). This vertical lever is pivoted at the bottom, its movement translating into fore and aft movement of the internal plate. In the forward position, the internal plate engages slots in the rear of the trigger blades, thus blocking their movement. When the safety is pulled to the rear, the plate also moves to the rear, disengaging the trigger blades and allowing their movement. The internal plate has a stud that serves to block its movement back to the "safe" position by the raised right trigger blade when the right barrel is fired.

It's a fairly cumbersome device to use as the "safe" and "fire" positions seem counter-intuitive. Safe is forward and fire is to the rear.